Autosamdri®-815B, Series B

- The Supercritical Autosamdri®-815B, Series B System was developed by Dr. A. J. Tousimis and our team of long-standing associates within the tousimis® SAMDRI design group.

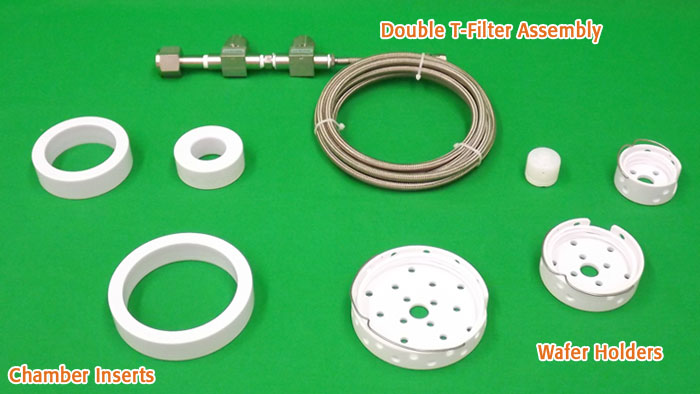

- Smooth operation and precise control are the Supercritical Autosamdri®-815B´s trademark; wafer holders and inserts are provided that allow anti-stiction processing up to 5 pieces of either 4" (100mm), 3" (75mm), 2" (50mm) wafers or 10mm square die per process run!

- Process up to 4" (100mm) wafers

- Automatic Supercritical Point Dryer

- Minimal Facility Utility Requirements

- Made in U.S.A.

- Microprocessor controller allows for complete automatic processing.*

- All internal surfaces are inert to CO2 and ultra pure alcohols.*

- Repeatable operating parameters insuring reproducibility of results.*

- Integrated temperature controls.*

- Internal rupture disc built in for safety. *

- Processes up to 5 x 4" (100mm) diam. wafers per run; comes with additional HF compatible wafer holders to process 5 x 3" (75mm), 5 x 2" (50mm) diameter wafers or 5 x 10mm square die (Tousimis HF compatible Wafer Holders* can be used to transport and process your wafers and die from HF).

- All electronic components meet CE, UL and/or U.S. Military Specifications.

- Static pressure control module pre-set for automatic safe pressure stability.

- 0.08µm internal filtration system delivers clean filtered LCO2 to process chamber. *

- Under-lit chamber with viewing window facilitates operator chamber status viewing.

- An efficient adiabatic cooling system*, capable of cooling the chamber from ambient room temperature to near 0°C, in less than 3 minutes and maintains temperature automatically during both FILL and PURGE modes.*

- LED's instantly indicate process mode at a glance.*

- Clean room static-free compatible design.

- For added safety and convenience, the U.S. Patented SOTER™ condenser* quietly captures exhaust and alcohols.

- Unique chamber inserts* allow variance of chamber I.D. This maximizes efficiency in LCO2 consumption and processing time.

- Cabinet: 14.25" (36.2cm) Width x 11.75" (29.8cm) Height x 25" (63.5cm) Length

- System Set-Up Area Required: 42" (107cm) Width x 30" (76cm) Depth

- Chamber size: 4.50" I.D. x 1.25" depth Chamber volume: 326 ml

- Temperature gauge range: -30°C to 60°C, Pressure gauge range: 0 to 2,000psi

- 120V/50-60Hz (Other voltage units also available. Please Inquire)

- LCO2 flow is controlled through Micro Metering Valves with Vernier handles for easily controlled flow rates.*

- LCO2 High Pressure braided stainless steel inert Teflon® lined hose. 10ft (~ 3m) long for clean room operation (at a nominal charge, other lengths available upon request).

- Double T-Filter Assembly (#8785) pre-installed onto the chamber LCO2 supply high-pressure hose. Flows LCO2 twice thru 0.5µm filters with 99.5% particulate retention prior to LCO2 entering Autosamdri®-815B.

- New SOTER™ Condenser* connects to exhaust hose. Captures all alcohol and deadens exhaust noise.*

- Static free Exhaust Tubing for all exhaust outlets.

- Internal stainless and nickel scintered filtration systems incorporated to protect lines, wafers, and valves down to 0.08µm.

- Spare Chamber O-ring (3), Chamber Lamp (1), and 5A Slo-Blow Fuses (2).

- 3 Chamber Inserts.* Enables original chamber ID reduction down to smaller chamber ID sizes for a range including: 4", 3", 2", and 1.25" !

- 4" (100mm), 3" (75mm), 2" (50mm) diameter Wafer Holders and 10mm square Die Holder included. Holders are HF compatible and can hold up to 5 wafers or die each.

- Free lifetime technical support consultation by our scientific staff.

- 2 year warranty on all parts and labor.

- 8760-02: :KNURL NUT for 4" and 6" Process Chamber

- 8760-40: :5 AMP FUSE for SAMDRI® Models: PVT-3D, 795, 815, 815B, 915B (Series A & Series B Only)

- 8770-10: :CHAMBER LAMP, 120Volt/60Hz

- 8770-32: :HIGH-PRESSURE HOSE, 5ft

- 8770-33: :HIGH-PRESSURE HOSE, 10ft

- 8770-60: :CHAMBER LID for 4" Process Chamber

- 8785: :Double T-Filter Assembly

- 8770-83B: :0.5µm Stainless Steel Particulate Filter Element for LCO2 T-Filter or External Purge Line Filter.

- 8784-05: :Gasket for LCO2 Tank Connect

- 8770-51T/815B: :O-Ring for Autosamdri®-934 and Autosamdri®-815B

- 8770-46: :Flow Meter - Use with any 2.5", 3.4" and 4.0" dia. Autosamdri® Chamber (60 SCFH)

- 8770-53: :POWER CABLE

- 8770-54: :LCO2 TANK SCALE W/ REMOTE DISPLAY

- 8770-56A: :Step-Down Transformer, 200-240V → 110-120V, 3000W

- 8770-83A: :Internal 0.5µm 316SS Particulate Line Filter

- 8768B: :4" - 100mm HF Compatible Wafer Holder

Holds 5 Wafers - 8768C: :3" - 75mm HF Compatible Wafer Holder

Holds 5 Wafers - 8768D: :2" - 50mm HF Compatible Wafer Holder

Holds 5 Wafers - 8768G: :1" - 25mm HF Compatible Wafer Holder

Holds 5 Wafers - 8768E: :10mm Square HF Compatible Chip Holder, Holds 5 Die