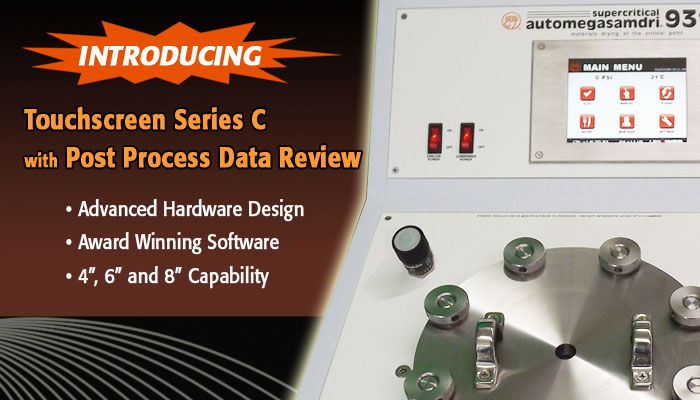

Touchscreen Series C

TOUSIMIS HAS NOW INTEGRATED OUR AWARD WINNING AUTOSAMDRI®-931 SOFTWARE TECHNOLOGY WITH THE NEW SERIES C LINE HARDWARE TO FURTHER ENHANCE THE SERIES C

THE TOUSIMIS 'SERIES C' LINE HAS LED THE WAY IN RELIABILITY, YIELD, AND EFFICIENCY FOR OVER 15 YEARS IN BOTH INDUSTRIAL AND RESEARCH FACILITIES WORLDWIDE

THE TOUSIMIS 'SERIES C' LINE HAS LED THE WAY IN RELIABILITY, YIELD, AND EFFICIENCY FOR OVER 15 YEARS IN BOTH INDUSTRIAL AND RESEARCH FACILITIES WORLDWIDE

- A dedicated slow fill line allows for ideal internal chamber fluid dynamics for the most sensitive devices

- Thermostatically controlled internal condenser

- Temperature controlled valving

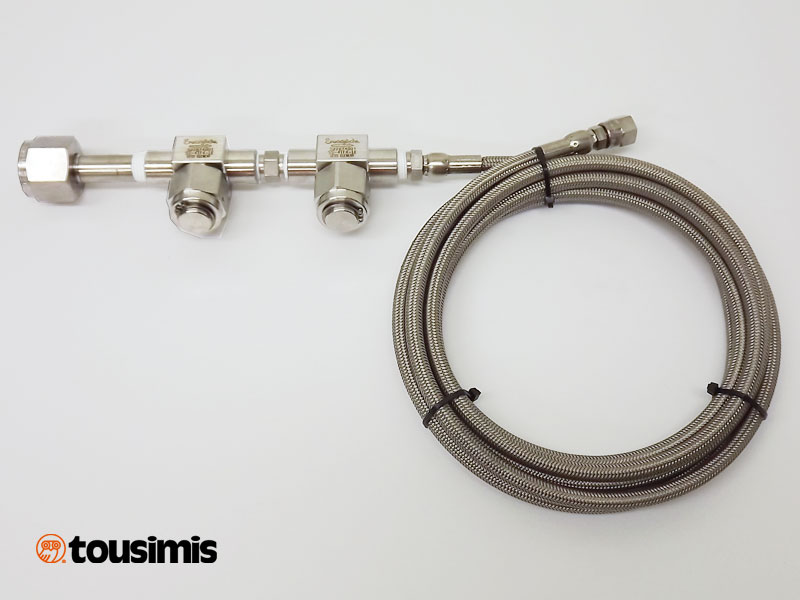

- Stainless steel tubing with an internal filtration system down to 0.08 µm to protect samples and system function

- Non mechanical stirring chamber allowing for fluid dynamic exchange without the need for particle generating friction causing devices

- Chamber flexibility with inserts and holders allowing for processing processing up to 8" wafers, pieces and die

- Made in U.S.A.

• Autosamdri®-934 (Cat #8788A)

Touchscreen control automated CPD system for up to 5 x 4" Wafers

Touchscreen control automated CPD system for up to 5 x 4" Wafers

• Automegasamdri®-936 (Cat #8788B)

Touchscreen control automated CPD system for up to 5 x 6" Wafers

Touchscreen control automated CPD system for up to 5 x 6" Wafers

• Automegasamdri®-938 (Cat #8788C)

Touchscreen control automated CPD system for up to 5 x 8" Wafers

Touchscreen control automated CPD system for up to 5 x 8" Wafers

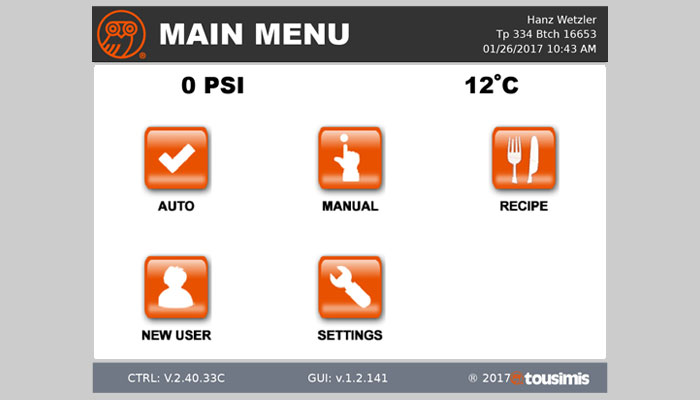

- Bright LCD Touchscreen Control

- Use Factory Default Automatic Settings or Create Custom Recipes

- Optional "Stasis Software" (Patent Pending) for versatile sample types

- Process up to 5 wafers per process run with each system

- HF Compatible Wafer Holders and 10mm square holder included with each system

- Tousimis® HF compatible Wafer Holders may be used to etch and process your wafers minimizing handling

- Unique chamber inserts easily reduce chamber ID decreasing LCO2 consumption

- High efficiency internal closed loop refrigeration integration

- "Vortex Swirl" non-mechanical purge stirring (Patent Pending) eliminates moving parts for easy maintenance

- Repeatable operating parameters insuring “reproducibility” of results

- Static pressure control module helps insure automatic safe pressure stability

- Internal filtration system delivers clean LCO2 into process chamber down to 0.08µm

- New 'Slow Fill' Control for the most delicate Sample Types

- LCO2 flow is controlled through Micro Metering Valves with Vernier handles for precise flow control and easy position setting readjustment

- Chamber illumination with view port facilitates chamber status visualization

- All internal surfaces are inert to CO2, Acetone and Ultrapure Alcohols

- Cleanroom static-free compatible design

- External mounted Post Purge Filter Assembly for EZ preventive maintenance maintenance

- The patented internal SOTER™ Condenser quietly captures and separates CO2 exhaust and waste alcohols

- All electronic components meet CE, UL and/or U.S. Military Specifications

Upcoming Exhibitions and Conferences

Booth #: 1233

Date: July 28-31, 2025

Location: Salt Palace Convention Center, Salt Lake City, Utah